Kiến thức cơ bản về khuôn thạch cao và tạo mẫu gốm

|

Porcelain mold plaster: Gypsum is generally white powdery crystals, as well as gray and reddish yellow crystals. It belongs to the monolithic crystal system. In terms of composition, it is divided into dihydrate gypsum and anhydrous gypsum. The ceramic industry mold production application is generally dihydrate gypsum. It uses the characteristics of dihydrate gypsum that it loses part of the crystal water after being calcined at a low temperature of about 180 degrees Celsius, and becomes a dry powder, which can absorb water and harden. Generally, the setting time for gypsum to be mixed and stirred evenly is 2 to 3 minutes, and the heat reaction is 5 to 8 minutes. After cooling, it becomes a strong and firm object. According to the “Xin Tang Book Geography” records, Fangxian in Hubei, Fenyang in Shanxi, and Dunhuang in Gansu all used gypsum in the Tang Dynasty. According to Tang Ying’s “Taoye Illustrated Illustration”, plaster mold making had developed into a specialized industry during the Qianlong reign of the Qing Dynasty. However, gypsum was used in ceramic production at the end of the Qing Dynasty and the beginning of the Republic of China. At that time, the Jingdezhen Ceramic Industry School first produced plaster models. The manufacture of ceramics is based on the actual needs of life. Before the production of ceramic utensils, it is necessary to conceive and plan according to various conditions and requirements in order to achieve the predetermined purpose. This is the beginning of ceramic modeling design. It is not the decoration of the surface, but the determination of the basic form and the various parts. The processing of mutual relations creates a real three-dimensional shape. It is not only different from surface modification, but also different from the realistic shaping of natural images. It uses various elements of modeling and follows certain rules and methods to create ceramic utensils that nature has not bestowed on mankind. Ceramic design: Ceramic design needs to be based on life, and the designer needs to have multiple identities such as user, appreciator, and producer at the same time. Moreover, ceramic modeling design is not arbitrary. It is also subject to many objective conditions, such as the physical chemistry of material materials. Performance, mechanics and thermodynamic properties, as well as the limitations of the molding process and the firing process, and it must meet certain practical requirements, such as the uniformity of accessories, the appropriate capacity, and the appropriate proportion of the shape. These all need to be considered by the designer. of. In the initial stage of ceramic modeling, it was mainly completed by simulation. It was an early modeling activity that had not yet formed a systematic modeling activity. However, it started the initial modeling vision and plan after all, and has integrated the production activities of material products and spiritual civilization. The creative activities are tightly integrated. After the emergence of ceramic modeling, the following three factors played a role: firstly, it was based on the needs of the living conditions and lifestyle at the time; secondly, it was inseparable from the level of science and technology and production capacity at that time; thirdly, it was people’s culture Aesthetic hobby of artistic accomplishment. This is not only a driving factor, but also a limiting factor. The design principles of ceramic modeling should follow the three elements of “economy, applicability, and beauty”, that is to say, ceramic modeling is composed of three elements: functional utility, material technology and formal beauty. Among them, functional utility is the first priority, which determines the basic form and structure of ceramic modeling. The material technology of ceramic modeling refers to the ceramic raw materials and process technology used. The beauty of ceramic modeling should be established on the basis that it meets the functional utility and is easy to produce. It does not deviate from the attributes and characteristics of the ceramic modeling itself. Starting from the objective and practical laws, the beauty of form, functional utility and material technology should be integrated. This is design In the process, always follow the principle. Ceramic modeling design is not a pure art design, but a unified overall design that includes the functions, craftsmanship and aesthetics of ceramic products. Functional utility occupies a dominant position in the entire design. Material technology is the guarantee for the realization of design intent. Formal beauty is to make the product appearance and form more perfect. It is impossible for the three to lack any aspect. This is also the most prominent feature of ceramic modeling. |

The three elements of ceramic modeling design:

Generally refers to: practicality, craftsmanship and aesthetics. The basic rules of ceramic modeling design:

(1) Stability:

- 1) When the center of gravity shifts down, the key lies in the height of the chest and abdomen;

- 2) Balance between vertical and horizontal;

- 3) The size and proportion of the sole surface of the modelling is appropriate. The test method is to see whether the lower part where the parallel lines at both ends of the upper shoulder of the model intersect with the diagonal lines at both ends of the bottom foot is greater than one third. The short-shaped objects fall on the bottom due to their own weight, so they are not restricted by this rule.

(2) The change and unification of shape:

- 1) Contrast;

- 2) Strengthen and weaken;

- 3) Rhythm and rhythm.

(3) Practicality of modeling:

- 1) Practical use must consider that different utensils have different uses and are subject to different needs;

- 2) For practical use, the aesthetic requirements and economic conditions of the use object must be considered;

- 3) Modeling capacity requirements are important standards for daily ceramics;

- 4) The dexterity of modeling is also one of the practical requirements.

(4) The scientific nature of ceramic modeling:

- 1) The change of the model structure should adapt to the minimum force limit (that is, the principle of mechanical requirements);

- 2) The modeling structure must pay full attention to the plasticity of its clay;

- 3) The design model must master the high-temperature firing changes of the raw materials used;

- 4) The connecting parts of the various parts of the modeling should be reasonable and simple;

- 5) The design must be easy to use, wash and clean.

Basic knowledge of model making

- 1.Understand the basic knowledge of ceramic design and production;

- 2. Analyze and research the excellent ceramic shapes in ancient and modern China and abroad;

- 3. Master the transformation of ceramic modeling from paper design to three-dimensional objects;

- 4. Understand the material characteristics of gypsum and master the steps of using it;

- 5. Master the method steps of making ceramic molds;

- 6. Master the method steps of ceramic model remaking;

- 7. Master the method steps of grouting;

- 8. Master the issues that must be paid attention to in each step.

(1) Preparation of gypsum slurry:

1. The characteristics of gypsum:

Gypsum is the main raw material for model making. It is generally white powdery crystals, but also gray and reddish yellow crystals. It belongs to the monoclinic crystal system. Its main component is calcium sulfate. According to the amount of crystal water, it is divided into dihydrate gypsum and Anhydrous gypsum, the ceramic industry mold production application is generally dihydrate gypsum, which uses the characteristics of dihydrate gypsum that it loses part of the crystal water after being calcined at a low temperature of about 180 degrees Celsius and becomes a dry powder, which can absorb water and harden. In addition to natural gypsum, there are also synthetic gypsum. Generally, the setting time for gypsum to be mixed and stirred evenly is 2 to 3 minutes, and the heat reaction is 5 to 8 minutes. After cooling, it becomes a strong and firm object.

Theoretically, the amount of water required for the chemical reaction of gypsum and water is 18.6%; in the process of model making, the actual amount of water added is much larger than this value. The purpose is to obtain a certain fluidity of gypsum slurry for pouring, and at the same time obtain A model with a smooth surface; excess water leaves many capillary pores after drying, making the plaster model water-absorbent.

Water absorption is an important parameter of gypsum model, which directly affects the forming speed during grouting. The water absorption rate of plaster molds for ceramics is generally between 38% and 48%.

Place the gypsum powder in a dry place. Do not splash water or turned gypsum during use. The gypsum bag should be clean to prevent used gypsum residue or other sundries from being mixed into the bag.

2. Porcelain mold plaster:

Gypsum is generally white powdery crystals, as well as gray and reddish yellow crystals. It belongs to the monolithic crystal system. In terms of composition, it is divided into dihydrate gypsum and anhydrous gypsum. The ceramic industry mold production application is generally dihydrate gypsum. It uses the characteristics of dihydrate gypsum that it loses part of the crystal water after being calcined at a low temperature of about 180 degrees Celsius, and becomes a dry powder, which can absorb water and harden. Generally, the setting time for gypsum to be mixed and stirred evenly is 2 to 3 minutes, and the heat reaction is 5 to 8 minutes. After cooling, it becomes a strong and firm object.

According to the “Xin Tang Book Geography” records, Fangxian in Hubei, Fenyang in Shanxi, and Dunhuang in Gansu all used gypsum in the Tang Dynasty. According to Tang Ying’s “Taoye Illustrated Illustration”, model making had developed into a specialized industry during the Qianlong reign of the Qing Dynasty. However, gypsum was used in ceramic production at the end of the Qing Dynasty and the beginning of the Republic of China. At that time, the Jingdezhen Ceramic Industry School first produced plaster models. The manufacture of ceramics is based on the actual needs of life. Before the production of ceramic utensils, it is necessary to conceive and plan according to various conditions and requirements in order to achieve the predetermined purpose. This is the beginning of ceramic modeling design. It is not the decoration of the surface, but the determination of the basic form and the various parts. The processing of mutual relations creates a real three-dimensional shape. It is not only different from surface modification, but also different from the realistic shaping of natural images. It uses various elements of modeling and follows certain rules and methods to create ceramic utensils that nature has not bestowed on mankind.

3. Modulation of gypsum slurry:

- 1) Prepare the basin and plaster powder;

- 2) Add an appropriate amount of water to the basin, and then slowly sprinkle the gypsum powder into the water along the edge of the basin. Be sure to add water first and then gypsum in the order.

- 3) Until the gypsum powder emerges from the water surface and no longer naturally absorbs water and sinks, wait a while and use a stirring rod to stir it quickly and vigorously and evenly. Just make it into a paste.

- 4) The ratio of gypsum during preparation is: gypsum slurry for general car manufacturing, water: gypsum=1:1.2~1.4; gypsum slurry for cutting, water: gypsum=1:1.2 or so; gypsum slurry for model rebuilding, Water: gypsum=1: about 1.4~1.8.

- 5) Pay attention to picking out the lumps and impurities in the gypsum slurry.

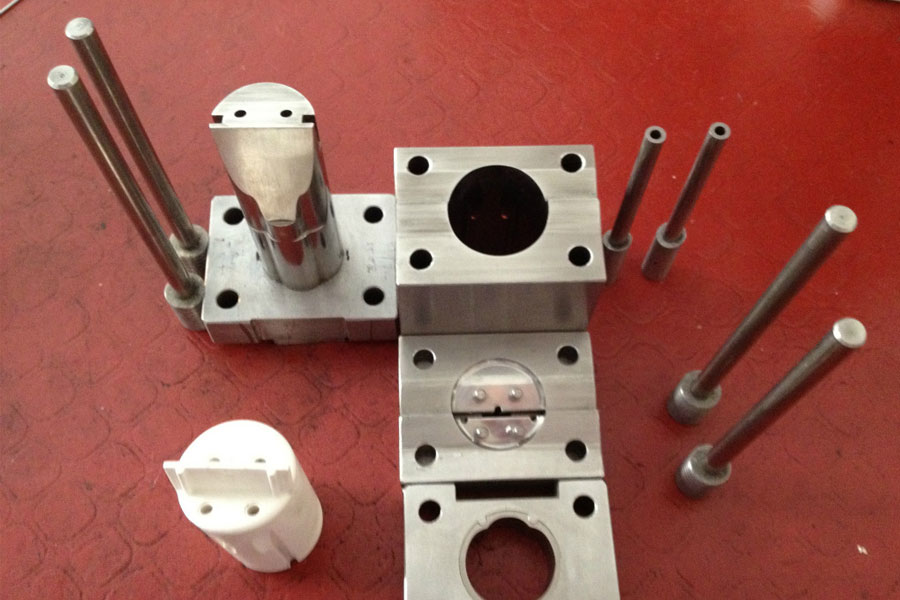

Model car system:

1. Equipment tools:

(1) Car model machine

The round tool model mainly adopts the vertical car model locomotive model. The car model machine is divided into bracket type and arch arm type, among which the bracket type car model machine is commonly used. The requirements of model making for the car model machine are: it must have a high degree of concentricity; it requires good stability and can withstand larger loads; it requires a flexible brake mechanism; the wheel head of the car model machine must be fastened and cannot be loosened.

(2) Tool

The commonly used knives for model making include: triangle knives, square knives, hacksaw knives, bamboo knives, etc. Sometimes it is necessary to temporarily polish some special-shaped tools according to the needs of the mold.

Triangular knife is the main tool for turning round tool molds. The material is generally cut into 50-60 mm equilateral triangles with 4~5 mm 45*, 50* steel, and welded with round steel with a diameter of 8~10 mm and a length of about 400 mm. A wooden handle is installed at the rear to facilitate Hold.

Model making requirements for tools:

- a. The tool is generally required to be opened at an angle of ≤45 degrees;

- b. The cutting edge line should be kept in a straight line (except for special-shaped tools);

- c. The edge of the knife should be polished flat;

- d. The shank and the handle should be firmly connected;

(3) Auxiliary tools

Commonly used auxiliary tools for model making include: oil felt, stabilizer bar, gypsum slurry basin, water-resistant sandpaper, hacksaw blade, pencil, hard board, wire saw, rope, clip, etc.; commonly used quantities include: internal and external calipers, rulers, triangles, compasses, etc. .

2. Model car production:

The model turning in model making is a semi-mechanical and semi-manual turning shape. Therefore, students are required not only to master general turning principles and operating methods, but also to have certain skills. The model car system is mainly operated by hand. Therefore, here is a brief introduction to the operation methods and steps for students’ reference.

(1) Preparation for model car system

- a. Prepare tools, water and plaster, clean the car model machine table, fix the production drawing on the frame with clamps or nails, and clean the triangle claw plate of the car model machine.

- b. According to the maximum diameter of the model, release a margin of 2 to 4 mm, and fill the mud under the triangular claw plate, and fill it in a circle as much as possible. The purpose is to make a table for enclosing the oil felt, and not to leak the gypsum slurry into the mang of the claw plate.

- c. Cut the linoleum according to the height of the shape. Use a rope to wrap the linoleum on the filled mud platform. Be sure to tie it tightly and fill the gap with mud to prevent the gypsum slurry from leaking.

- d. Slowly pour the stirred gypsum slurry into the enclosed linoleum cavity, and then use a thin rod to insert it and stir gently to release the bubbles inside.

(2) Model car system operation

a. When turning, stand with your legs apart to stabilize your body; in order to hold the tool, you must use the stabilizer bar and your body’s strength to stabilize the tool. Generally, the stabilizer bar is placed on the right shoulder, and the front end of the stabilizer bar is placed on the fixed plate of the lathe; the left hand holds the front end of the tool and the stabilizer bar firmly, and the right hand stabilizes the tool holder at the rear. The tool is fixed on the stabilizer bar on one side. The tool touches the plaster column during turning.

b. The claw plate of the general lathe machine rotates counterclockwise, so the tool is generally on the right side of the plaster column; in the turning process, the tool handle and stabilizer bar must be tightly held, and the shoulder should also be tightened against the stabilizer bar. Will reduce the phenomenon of jumping knife and shaking.

c. After the gypsum slurry has solidified a little, remove the linoleum, first use the turning tool to turn the plaster column round and flat; then turn the prototype, generally leave a machining allowance of 1 to 2 mm, and only perform the fine turning after the basic shape is turned. . And use water-resistant sandpaper to finely polish and smooth.

d. Knife operation:

- a.Longitudinal knife: It is the main method of turning the outer circle of the plaster column. Except for the hands and shoulders to grasp the handle and stabilizer bar, the knife should be inserted from the tangent direction of the outer surface of the plaster column and move at a constant speed from top to bottom. Stand upright with your feet separated by a certain distance, and your knees should be gradually bent at a uniform speed to make a horse stance. At the same time, you must maintain a uniform force to ensure that the knife tip moves in a straight line at a uniform speed. Generally use the tip for rough turning and the blade for fine trimming.

- b.Cross knife: It is mostly used when turning the top surface of plaster column. When entering the tool, it generally starts from the center of the circle and turns outward with the help of centrifugal force; it can also turn from the outside to the inside. Separate your feet during operation, and move your body’s center of gravity from left to right or from right to left. The force must be uniform to ensure that the blade or tip of the knife moves horizontally and at a constant speed.

- c.Arc cutting: According to the specific requirements of the shape of the mold, the tool feeds and turns at a certain angle. Generally, the tool feeds from the part with a large amount of cutting, from the depth to the shallower, and from the fast tool to the slower. The tool moves in a circular arc according to the radian requirements of the model. Generally use the tip of a knife for rough repair, and use the round blade of a square knife for fine repair.

- d.Turning groove: generally use the tip of a triangular knife to turn. Sometimes the tool is filed temporarily according to the drawing of the model. At this time, you must be very careful, you should use the full lunge position turning.

- e.The contour curve of the utensil can be cut out with a rigid board according to the drawing, and then it can be compared with the car on the plaster model.

- f.After the inspection is completed and the drawings are correct, cut in parallel with a hacksaw blade. Generally, the lathe machine can be used for rotary cutting.

- g.If the mold type is allowed, the mold type can be turned upside down, so that the bottom foot can be cut directly; the foot can also be dug out by hand. Generally, the shape of the thick neck and no more accessories can be used to make up the bottom of the car after cutting. The method is to accurately measure the caliber of the mold, and turn the plaster chassis on the car model machine into a base of the same size as the caliber. The center is required to be low and the edge is high. Then put the model upside down on the base of the car, be sure to align the edges, apply a release agent on the model and the base, adjust the thick plaster paste, and then car out the foot.

- h.Clean the table tops, knives, etc. of the lathe, and clean up the waste plaster.

(3) Mold cutting operation:

Special-shaped molds mainly refer to shapes that cannot be turned by a turning machine at one time. The production method mainly adopts manual modeling or mixed modeling (that is, a combination of manual and mechanical).

The main production steps are:

- a. Place the drawing face up on a flat workbench, and then cover it with a transparent glass plate.

- b. Beat the mud into mud pieces of moderate thickness, enclose a modeling cavity on the glass plate according to the drawings, and leave a machining allowance of 1 to 2 mm on the edge. The height of the mud piece is subject to the maximum thickness of the model, and there should be a margin. Then plug it around to avoid gypsum leakage.

- c. Prepare gypsum slurry, slowly pour it into the mud-enclosed cavity, and then gently stir it with a thin rod to release the bubbles inside.

- d. After the plaster has solidified a little, remove the mud enclosure. Scrape the upper end with the teeth of the saw blade.

- e. Remove the plaster block from the glass plate, take the side close to the glass as the reference plane, and the upper end surface should be parallel to it; the other surfaces should be perpendicular to it.

- f. Then measure the required width upward from the reference plane; determine the center line.

- g. Manually cut according to the midline. The symmetry is based on the center line; the rest of the shapes are cut according to the design drawings.

- h. Finally, smooth it with water-resistant sandpaper.

Requirements: The mold type meets the design requirements and process requirements, and the surface is smooth, without openings and cracks, and as far as possible without defects such as pores and trachoma.

(4) Model copy operation:

Commonly used materials and tools are: bamboo knives, hacksaw blades, saw blade knives, ruler triangles, writing brushes, oil felts, mold release agents, etc.

- a. Clean the workbench, clean up the plaster mold, and use a pencil to gently draw the parting line on the surface of the model according to the pre-made plan. This is a very important step. The principle is that on the basis of being able to open the mold, the less blocks the better.

- b. For general modeling, first turn over a large mold, use mud to base, and enclose the modeling. According to the parting line, use a bamboo knife to smooth the mud surface. The mud surface should be one line below the parting line.

- c. Spread the release agent evenly on the plaster mold, and pay attention to all parts must be evenly coated and not missed.

- d. Use a template or oil felt to enclose the outer edge of the mold, and the distance from the maximum diameter of the mold should be appropriate. Generally, for molds with a height of 300 mm, the edge thickness of the mold is about 40 mm. Note that there should be no gaps in the template or oil felt. It should be stuffed with mud.

- e. Apply release agent on the mold and tie it tightly with a clip or rope. The grouting port is reserved according to the modeling requirements, which can be kneaded into a round table shape for use.

- f. Prepare gypsum slurry and slowly pour it into the enclosed cavity until the mold is submerged and added to a suitable thickness. After the plaster has solidified a little, remove the template or felt, and smooth the outside of the mold with a hacksaw blade.

- g. To open the mouth on the side of the mold, you can use trapezoid, triangle, circle, etc., to carve and smooth, and it must be wide at the top and narrow at the bottom, so that another mold can be opened.

- h. Apply release agent on the mold model, surround it with a template or oil felt, pour another mold, and so on, until the integrated mold is poured. After each mold is poured, it must be smoothed with a hacksaw blade in time. The spigots of the mold should be anastomosed, and the division should be symmetrical.

- i. After the mold is rebuilt, leave it for a period of time, and after the gypsum heat reaction cools down, the mold can be opened to take out the mold. If it is not easy to open, it can be opened by tapping, water brewing and other methods. After opening, the mold must be rinsed with water to remove the release agent on the inner wall, and placed in a drying room for drying. The temperature during drying must not be higher than 60 degrees Celsius to prevent the mold from being powdered and scrapped.

Note: The whole process of making molds requires boldness and carefulness, and you must remember to apply release agent, open the mouth, and flatten. The mold is required to be smooth as a whole, with a smooth surface, and a smooth interior, and no flying edges and burrs are allowed.

(5) Grouting and forming operation:

The grouting molding mainly uses the characteristics of the gypsum mold to absorb water, so that the mud is adsorbed on the mold wall to form a uniform mud layer, which reaches the required thickness within a certain period of time, and then dumps the excess mud and the remaining mud in the mold The layer moisture continues to be absorbed by the gypsum mold and gradually hardens, and after drying, the volume shrinks and separates from the mold, and a good rough body is obtained.

- a. Mud: Mix the dried porcelain mud with water according to the proportion. Generally, the moisture content is about 39%. Leave it for more than one day to make the porcelain mud fully absorb water. Then add about 0.3% sodium humate or water glass and stir. For chemical pulp, there should be no mud or impurities in the pulp, and no water can be added at will.

- b. Tie the dried gypsum mold with a belt or rope, and place it on a flat table with the grouting port facing upwards. Use a grouting bucket to slowly inject the slurry. Pay attention to the mold joints not to run the slurry, in case this occurs In this case, it is necessary to use the mud block in time.

- c. Pay attention to adding slurry at any time, and don’t make the slurry sink too much, so as to avoid uneven thickness of the utensils.

- d. When the mud is adsorbed to a certain thickness in the mold, it is usually about 3~5mm to pour the mud. The pour should be slow and must not be rushed to avoid peeling off the adsorbed mud layer on the mold. Turn the mold gently to avoid inconsistencies in the thickness of the mouth.

- e. After pouring the slurry, in addition to the outsole shape and the inconvenient inverted shape, the mold is generally placed upside down on the table, called empty slurry, and left for about 5 minutes.

- f. After being placed for a certain period of time, generally when the grouting port of the mold is separated from the blank by 0.5 to 1 mm, the mold can be opened in reverse order of clamping, and the blank can be taken out carefully.

- g. Trim the grouting mouth of the mud blank, cut off the excess part, and flatten the parting line.

- h. Put the mud on a pallet or platform, and dry it in the drying room or dry it naturally for later use.

Note: No debris can be mixed in the mud; during grouting, it is not advisable to inject too quickly; the internal surface of the body should be flat and smooth, and no obvious defects such as mud blocks are allowed; the cut grouting port and other mud cannot be directly put into the grouting Slurry bucket.

(6) Các vấn đề cần chú ý:

- 1. The gypsum powder should be placed in a dry place, and the gypsum bag should be clean to prevent the used gypsum residue or sundries from being mixed into the bag.

- 2. Add water and gypsum in strict accordance with the order.

- 3. Pay attention to holding the props tightly to prevent the knife from jumping when turning.

- 4. The mold type meets the design requirements and process requirements, the surface is smooth, no openings and cracks, and as far as possible without defects such as pores and trachoma.

- 5. Clean up the table tops and cutters of the lathe in time.

- 6. When reworking the mold, you must always remind yourself to apply release agent, open the mouth, and level it.

- 7. After the mold is rebuilt, the overall surface should be smooth, the surface should be flat, and the interior should be smooth (the joint part of the mold is not allowed to be polished or scraped later), and no edges and burrs are allowed.

- 8. No impurities can be mixed into the grouting slurry, and the filter should be used before it can be injected into the mold.

- 9. When grouting, inject the mold slowly, not too quickly.

- 10. The internal surface of the grouting body should be flat and smooth, and no obvious defects such as mud blocks are allowed.

- 11. The cut grouting port and other mud debris can not be directly put into the grouting barrel, and should be filtered and used after re-sizing.

The water absorption rate of plaster molds for ceramics machining is generally between 38% and 48%

Gypsum slurry for vehicle manufacturing water: gypsum=1: 1.2~1.4

Gypsum slurry for cutting water: gypsum=1:1.2

Gypsum slurry for model rebuilding Water: gypsum=1: 1.4~1.8

The diameter of the lathe tool handle is 8-10 mm, and the length is about 400 mm

When the mold is dried, the temperature must not be higher than 60 degrees Celsius

Maintenance and maintenance of plaster models

- 1. Before grouting, when buckling and wiping the mold, it should be noted that the opposite surface of the model must be cleaned, and the edges and corners of the model must be protected to prevent wear. All kinds of model clamps should be tightly tightened properly. If the clamps are loose, they will open the model, and if the clamps are too tight, the model will collapse.

- 2. After the wet blank is uncovered, the running mud on the seam must be cleaned up with a soft material in time, otherwise it will accumulate and thicken and cause the model to deform.

- 3. Long-term use of a wet model not only does not guarantee the quality of the blank, but also is very harmful to the model itself. It will cause the model to age prematurely and greatly shorten the service life. This is because the model has a large water content. The salt inside the model reacts chemically with the dihydrate gypsum. CaSO4+Na2CO3=CaCO3↓+Na2SO4 This will cause severe corrosion and damage to the internal structure of the model.

- 4. The wet model is easy to deform during the drying process. The wet model that is removed and concentrated and dried should be placed carefully. It is best not to place it in blocks. The mud edge should be cleaned up, the clamps should be tightened, and the wet model should be placed reasonably. Tighten the clamp again, so that the originally loose model can fit very tightly. On the contrary, more serious deformation may occur. This is what the old grouting workers said, “the mold with a loose mouth can be made tighter, and the mold with a tight mouth can run out of grout.”

- 5. In production, we often encounter the phenomenon of “chalking” in the later stage of model use, that is, the phenomenon of pulverization and shedding on the outside of the model. The reason for this phenomenon is mainly due to the drying process of the model with the inner part of the model. Moisture moves toward the surface of the model. When the water evaporates into the air, a small part of these salts are deposited on the surface of the model in the form of alkali wool, and most of them stay in the voids on the surface of the model.

As time goes by, these salts accumulate and chemically react with the model, causing the model to pulverize. The methods to prevent pulverization are as follows:

- ①Appropriately reduce the drying speed of the model, so that the moisture can evaporate evenly from around the model;

- ②Adopt the method of pre-clamping and let the model dry at night. If the model is not suitable for pre-clamping because the model is wet, plastic cloth can be covered on the top of the core to prevent a large amount of moisture from evaporating from the apex;

- ③Scrape off a layer of the outer pulping surface of the model to increase air permeability and make the moisture evaporate outside the pulping surface.

Grouting: It is made into a fluid slurry with water, etc., and the slurry is poured into the porous plaster model. The water penetrates into the plaster model through the contact surface, forming a hard layer on the surface. This is a molding method in which the shape of the inner surface of the plaster mold is the same as the shape of the molded body. It is divided into double-sided grout method (solid grouting method) and single-sided grout method (hollow grouting method). This method has long been used in the production of ceramics. Grouting production requirements for environmental temperature and humidity: Grouting is a molding method with wide adaptability and high production efficiency. It can be used for any complex or irregular shape that cannot be molded by other methods and thin tire products. It is produced by molding, but because temperature and temperature have a great influence on the molding of the blank, it is directly related to the quality and survival rate of the semi-finished product. Therefore, the environmental temperature and humidity must be strictly controlled during production, and corresponding measures must be taken for seasonal changes. .

Requirements for environmental temperature and humidity:

The operating temperature in the grouting sanitary ware is generally controlled at 25℃-37℃. The temperature at night can be increased, but it should not exceed 50℃, because the outer surface of the green body will dry too fast if it exceeds 50℃. The drying speed of the inner surface of the body is relatively slow, which causes uneven shrinkage of the body during the drying process, resulting in cracking of the body during the drying process. Moreover, the shape of the plaster mold is complex, and the dry humidity of each part is uneven. During the molding process, it is easy to cause defects such as too fast eating and increased porosity of the green body after molding. The operating temperature in the molding is generally controlled at 50-70%. If it is high, the drying speed of the green body is too slow, which will affect the normal progress of the next process. If the green body is too low, the drying speed will increase, and the shrinkage speed will also increase, which is prone to cracking, especially for products with complex molding. severe.

Seasonal requirements of the grouting body:

The quality of the green body formed by grouting is more sensitive to seasonal changes, especially the spring and autumn seasons have the greatest impact on green body forming, because the wind in spring and autumn is relatively strong and the air is relatively dry. Under such conditions, if reasonable measures are not taken, The green body causes a large area of wind cracks in the forming stage, which seriously affects the yield of the green body. The main reason is that the wind cannot blow evenly to all parts of the green body, causing uneven drying of various parts of the green body, and local shrinkage too fast and cracking. Therefore, the issues that should be paid attention to during the spring and autumn seasons are:

- 1. The molding workshop should not open the window and door curtains to prevent the outside wind from directly blowing on the inner body. If necessary, all the blanks can be covered with film, so that the shrinkage will be uniform during the drying process.

- 2. In spring and autumn, spray some water around the molding operation frequently. The purpose of spraying water is to increase the humidity inside. The amount of spraying water is required to spray less at the beginning of the spring and autumn seasons, and gradually increase, and slowly decrease when approaching summer and winter, but pay attention to spraying less or even not spraying on cloudy and rainy days. The summer wind is relatively small and the humidity is relatively high. You can open the windows without spraying water inside. In winter, the windows must be sewn and glued to ensure the internal temperature.

Therefore, as long as we take corresponding protective measures according to seasonal changes and control the temperature and humidity in the production environment during the production process, it is very beneficial to improve product quality and yield.

Cửa hàng PTJ CNC sản xuất các bộ phận có tính chất cơ học tuyệt vời, độ chính xác và độ lặp lại từ kim loại và nhựa. Phay CNC 5 trục có sẵn.

Cửa hàng PTJ CNC sản xuất các bộ phận có tính chất cơ học tuyệt vời, độ chính xác và độ lặp lại từ kim loại và nhựa. Phay CNC 5 trục có sẵn.