inconel 718 là gì

|

Inconel 718 is a nickel-based alloy that can be hardened by precipitation. It still exhibits high yield strength, tensile strength and creep cracking strength at high temperatures up to 704 ° C. The age hardening reaction of 718 alloy is slow, so it will not harden with heating and cooling during annealing and welding. Compared with other nickel-based superalloys added with aluminum and titanium, 718 alloy has excellent welding performance. |

AMS5662 is the initial state of 718 and the softest state in the AMS class. Through heat treatment, AMS5662 can be converted into AMS5663. There are two heat treatment methods, one can optimize the impact performance, and the other can optimize the tensile and creep cracking performance. The hardness of AMS5662 is about 20-25HRC, which can be increased to 36-44HRC through aging treatment.

The difference between AMS5664 and AMS5662 and 5663 is larger, it is a different material, which involves a more complex forming process, so that the material has higher tensile and yield strength, while meeting certain grain structure requirements. AMS5664 is suitable for aerospace applications that require higher strength.

Inconel 718 Các Ứng Dụng

Jet engines and high-speed fuselage parts, such as wheels, turbine blades, gaskets, high-temperature bolts, dây buộcs, v.v.

Inconel 718 Nhiệt khí

1021-1052 ° C solution annealing for 1-2.5 hours, then water quenching. Bars with a diameter less than 3.5 “can be quenched with water or air-cooled. Aging for 6-8 hours at 774-802 ° C, then air-cooled

Inconel 718 Hành vi cơ học

Tensile strength: 150ksi or more

Yield strength: 120-145ksi

4D elongation: more than 20%

Section shrinkage (dia≤10 ”): 35% or more

Section shrinkage (dia > 10 ”): more than 25%

Độ cứng: 30-40HRC

V-notch impact strength (-59 ° C or lower):

Average energy: more than 35ft / lbs (47J)

Single minimum energy: 30ft / lbs (40J)

Inconel 718 Tính chất vật lý

Mật độ: 8.44

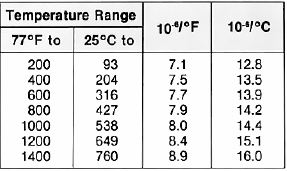

Hệ số giãn nở nhiệt trung bình

77-200 ° F 7.10 X 10-6in / in / ° F

77-400 ° F 7.50 X 10-6in / in / ° F

77-600 ° F 7.70 X 10-6in / in / ° F

77-800 ° F 7.90 X 10-6in / in / ° F

77-1000 ° F 8.00 X 10-6in / in / ° F

77-1200 ° F 8.40 X 10-6in / in / ° F

77-1400 ° F 8.90 X 10-6in / in / ° F

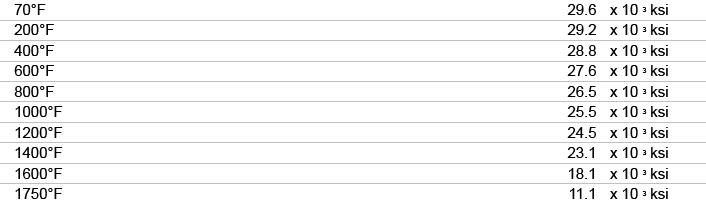

Elastic Modulus (E)

Resistance (70 ° F): 728.0 ohm-cir-mil / ft

Khoảng cách nóng chảy: 2200-2450 ° F

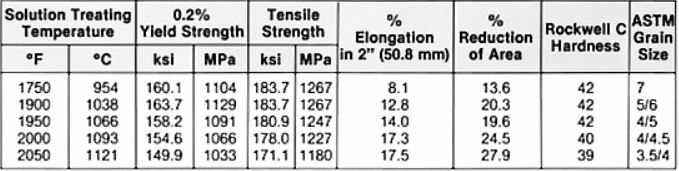

The effect of solution treatment temperature on the transverse room temperature performance of 718 material

Note: The test sample is a four-square piece with a side length of 4 “. The test sample is solution-treated for 2 hours at the temperature in the table and air-cooled. The aging treatment is 718 ° C for 8 hours and 56 ° C / hour The speed is cooled to 621 ° C, kept for 8 hours, and then air-cooled.

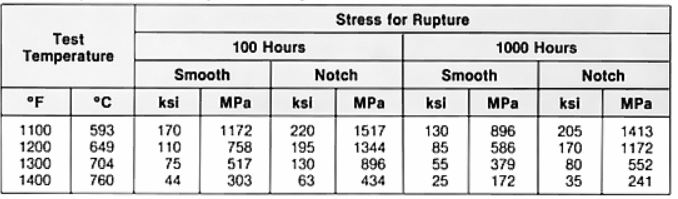

The effect of solution treatment temperature on the transverse stress cracking performance of 718 material

Note: The test sample is a four square piece with a side length of 4 “. It is solution treated at the temperature shown in the table for 2 hours, air-cooled, then aged at 718 ° C for 8 hours, and furnace-cooled at a rate of 56 ° C / hour Up to 621 ° C, heat preservation for eight hours, and finally air-cooled.

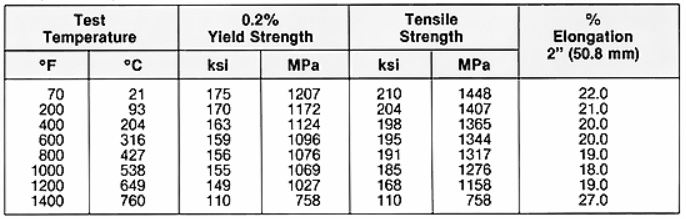

Heating tensile test

Note: The test sample is a dia12.7mm round bar, heat treated at 982 ° C for 1 hour, air-cooled at + 718 ° C for 8 hours, cooled to 621 ° C, kept at heat for 8 hours, and then air-cooled.

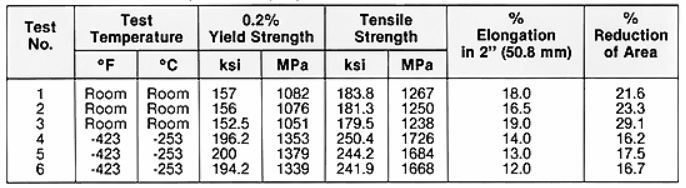

Low temperature tensile test

Note: The test sample is a four square material with a side length of 101.6mm. It is heat-treated at 1066 ° C for 2 hours, air-cooled at + 718 ° C for 8 hours, and cooled to 621 ° C in the furnace for 8 hours and then air-cooled.

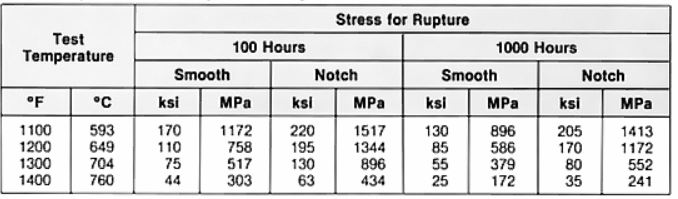

Stress cracking test

Note: Heat treatment at 982 ° C for 1 hour, air cooling + 718 ° C for 8 hours, furnace cooling to 621 ° C, heat preservation for 8 hours, then air cooling.

Nhiệt khí

Method 1: Obtain the best tensile strength and stress cracking strength

954-982 ° C, 1 hour, air-cooled + 718 ° C, 8 hours, cooled to 621 ° C at 56 ° C / hour, kept for 8 hours, then air-cooled.

Method 2: Obtain the best tensile strength at room temperature and low temperature

Heat treatment at 1066 ° C for 1-2 hours, air cooling + 718 ° C for 8 hours, cooling to 621 ° C at 56 ° C / hour, holding for 8 hours, then air cooling.

Hiệu suất xử lý

Quá trình tỏa nhiệt

The temperature of the hot processing furnace does not exceed 1121 ° C. If the working temperature is below 593 ° C, the temperature range of cold working is controlled at 927-1010 ° C, which can provide rèn strength. Avoid long-term heating in the furnace during rèn.

Máy Plus

Both annealed and age-hardened states can be machined. Age hardened state is more convenient to break, and the surface finish is better. For annealed materials, the machine tool life is slightly longer.

sự hàn

Both 718’s annealed state and aging state can be welded. When welding aged materials, the areas softened by the welding heat will deform.

Cửa hàng PTJ CNC sản xuất các bộ phận có tính chất cơ học tuyệt vời, độ chính xác và độ lặp lại từ kim loại và nhựa. Phay CNC 5 trục có sẵn.

Cửa hàng PTJ CNC sản xuất các bộ phận có tính chất cơ học tuyệt vời, độ chính xác và độ lặp lại từ kim loại và nhựa. Phay CNC 5 trục có sẵn.