Nghiên cứu về công nghệ quay trục thanh mảnh bằng hợp kim Ni-Si

|

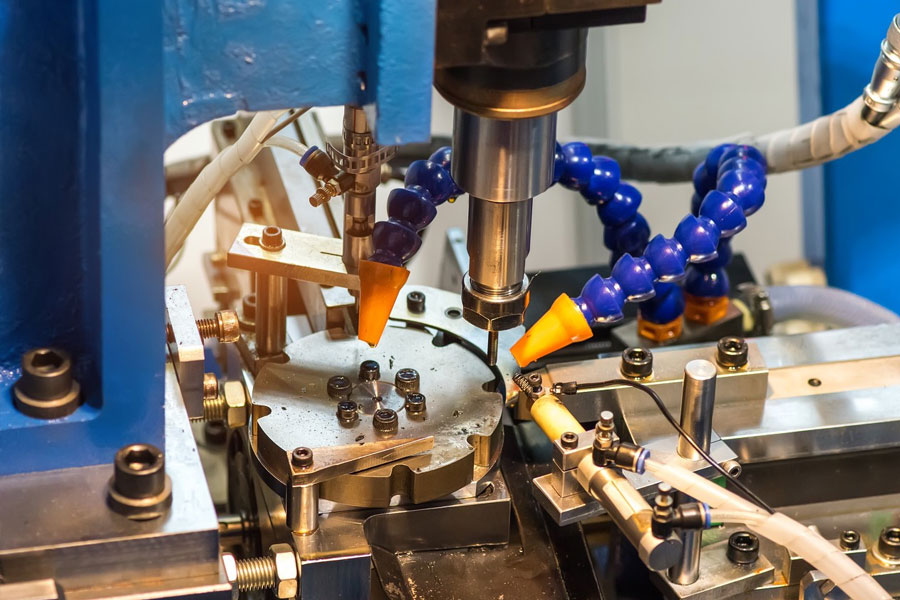

Nickel-silicon alloy is a typical high-temperature alloy. It is a difficult-to-process material and is widely used in aerospace, aviation and other fields. Its cutting is a difficult point in modern machining technology. Combining the characteristics of nickel-silicon alloy materials, taking a company’s nickel-silicon alloy contacts as an example, the turning processing technology has been studied, and a certain high-temperature alloy material processing technology has been reserved for the workshop, which has certain application value. |

1. Giới thiệu

High-temperature alloys are also called heat-resistant alloys or heat-strength alloys. It is a complex multi-component alloy based on iron, nickel, cobalt, titanium, etc., and can work under high temperature oxidation environment and gas corrosion conditions of 600~1000℃. Moreover, it can work for a long time under certain stress, and has excellent thermal strength, thermal stability and thermal fatigue performance.

However, high-temperature alloys are typical difficult-to-cut materials, with hardness higher than 250HBS, strength σb>0.98GPa, elongation δ>30%, impact value ak>9.8×105J/m2, thermal conductivity k<41.9W/(m2℃) , High temperature resistance directly increases the difficulty of processing. Under the combined action of large cutting force and high temperature during processing, the tool generates fragments or deformation, and then breaks; in addition, this type of alloy will quickly produce work hardening phenomenon, and the workpiece will be produced during processing. The hardened surface of the tool will cause the cutting edge of the tool to produce gaps in the depth of cut, and cause undesirable stress on the workpiece, and destroy the geometric accuracy of the machined parts.

2. Current situation analysis

Foreign scholars have done a lot of research on the cutting of superalloys. In 1939, the British Mond Nickel Company (International Nickel Company) first developed the nickel-based alloy Nimonic 75, and then the Nimonic 80 was successfully used in the blade material of turbojet engines, forming the Nimonic nickel-based alloy series. In early 1940, the United States developed Hastelloy B nickel-based alloy for use in GE’s Bellp-59 jet engine. In 1950, American PW Company, GE Company and Special Metal Company developed Waspalloy, M-252 and Udmit 500 alloys respectively, and formed Inconel, Mar-M and Udmit grades on this basis, which are widely used in turbine blades. . From 1940 to the middle of 1950, the alloy composition was adjusted. 1950: The emergence of vacuum melting technology enabled the development of a large number of high-performance casting superalloys such as Mar-M200 and In 100. After 1960, the development of new processes such as directional solidification, single crystal alloys, luyện kim bột, mechanical alloying, and ceramic filtration isothermal rèn have become the main driving force for the development of superalloys. Similarly, domestic scholars have also done a lot of research. From 1956 to 1957, GH3030, GH4033, GH34 and K412 alloys were successfully trial-produced for WP-5 engines; in 1960, GH4037, GH3039, GH3044, GH4049, GH3128, K417 and other alloys were successively trial-produced. Successfully developed; also successively developed a batch of superalloys for various rocket engines; at the same time, superalloys began to be popularized and applied to civil industry sectors, such as diesel turbochargers, ground gas turbines, etc., and a batch of high-temperature resistant alloys were developed one after another. Abrasion and corrosion-resistant superalloys; in 1970, the trial production and research of superalloys have begun to take shape. Through the imitation, digestion and development of Soviet superalloys as the main alloy and its process quality, it has reached or exceeded the Soviet standard and actual level. All the materials required for the engine are based in China.

At present, the company’s kết nối and relays do not have high-temperature alloy shells. Suzhou Huatan supplies Halliburton and often processes high-temperature alloys. The Guiyang Product Division is responsible for cutting parameters, tool materials and angles, cooling and lubrication, and materials during the processing of high-temperature alloys. Systematic research on performance is insufficient, and systematic research on high-temperature alloy processing is urgently needed to lay the foundation for the mass production of high-performance kết nối in the future. Therefore, there is an urgent need to carry out research on high-temperature alloy processing technology to meet the actual production needs of the workshop.

3. Part structure analysis

The needle body parts of the slender thân cây require high mechanical strength and strong creep resistance at high temperature. The total length of the needle body is 32mm, and the diameters are respectively φ1.2mm, φ1.5mm, and φ1.58mm, which belong to the slender thân cây parts. , It is easy to deform during the processing, and the deformation needs to be controlled to meet the production requirements.

4. Tool selection

Since the processing of nickel-silicon alloy requires high hardness, tight texture, good heat transfer effect, and strong high temperature activity, especially at 600 ℃, it will form a solid solution with oxygen and nitrogen. When processing nickel-silicon alloy, the surface hardness will increase significantly. Has a strong abrasion effect. Due to the wear-resistance and high temperature resistance of coated tools, coating tools should be used as much as possible when processing such high-temperature alloy parts.

Coated cemented carbide tools are almost suitable for the cutting of various difficult-to-machine materials, but the performance of the coating (single coating and composite coating) is very different. Therefore, suitable coatings should be selected according to different processing objects Tool material. Diamond-coated cemented carbide and DLC (Diamond Like Carbon) coated cemented carbide further expand the application range of coated tools, and blindly choose new material blades out of actual processing needs, which may also increase processing costs and use new materials When inserting the blade, if the cutting speed and feed rate are incorrect, it will also affect the quality of the workpiece and the service life of the tool. Therefore, when selecting cutting inserts for difficult-to-machine materials, it is necessary to correctly evaluate the economics of processing and comprehensively consider the entire processing process.

Based on the analysis of tool selection, this article selects Kyocera special nickel alloy processing inserts and Sandvik special nickel alloy inserts for processing experiments. The performance of the cutting tools is shown in Table 1.

|

Họ tên |

Đặc điểm kỹ thuật mô hình |

Tip angle |

Tip R |

Vật chất |

lớp áo |

|

Kyocera Cylindrical Knife |

VBGT110301R-F PR930 |

35 ° |

0.1 |

PR930: Ultrafine particle base material |

TICN(PVD) |

|

Sandvik Cylindrical Knife |

VCGT110301-UM 1125 |

35 ° |

0.1 |

GC1125: A material used for higher toughness requirements |

TICN(PVD) |

5. Analysis of cutting fluid

The cutting fluid can be water-based cutting fluid, which has fast heat transfer and good fluidity. It is not possible to use chlorine-containing cutting fluid. It cannot be mixed with aluminum, zinc and its alloys, copper and tin during processing. If the cutting fluid contains Chlorine will decompose and release hydrogen at high temperatures during the cutting process, which will cause epidermal embrittlement after being absorbed by nickel, and may also cause high-temperature stress corrosion cracking of nickel alloys.

The workshop cutting fluid mainly uses the Flowserve brand, the model ECOCOOL EM5 is a milky white water-soluble cutting fluid, and its chemical composition is shown in Table 2. It can be seen from Table 2 that this cutting fluid is water-based, the main component is mineral oil, does not contain chlorine, and meets the requirements of machining nickel alloys. This cutting fluid can meet the requirements of nickel gia công hợp kim.

6.Gibbscam software programming

GibbsCAM is a CAM software for parts cnc machining, especially CAM processing solutions in the field of turning and milling. In addition to turning and milling, it also supports 2-axis to 5-axis milling, turning, linked milling multi-task machining and wire cutting. Its biggest feature is its concise interface, easy to learn and use, and the operation mode is very consistent with our craft habits. Entered the Chinese market in June 2008. Our company purchased the software in July 2009. It is mainly used in the company’s digital turning, digital milling, turning-milling composite and five-axis machining centers. This type of equipment has turning, milling, and drilling. , Boring, broaching (slots) and other functions, with X, Y, Z, C, E and A axes. The CAM software can be used for any multi-axis linkage to realize the processing of various complex parts. With the diversification and complexity of new parts, it is imperative to use programming software for NC programming. The tool path of the slender shaft part is shown in Figure 4.

7. Turning processing verification analysis

Since the slitting automatic turning belongs to one-cut turning in place, the cutting force is large, which causes the parts to be easily deformed and the surface quality is poor. It is necessary to inspect each part, modify the variation in time, and change the program parameters and tool compensation. At the same time, because the processing equipment is a longitudinal cutting automatic car, the equipment does not divide the rough and fine machining, and all the dimensional accuracy is processed in one pass, so higher requirements are placed on the tool performance.

When cutting nickel-chromium-nickel-silicon alloy, the cutting temperature is high, the tool durability is low, and the cutting speed has the greatest influence on the cutting temperature. Generally, the cemented carbide tool is kept at 650℃~750℃. Through several turning experiments, the following cutting parameters are obtained:

1) Cutting speed vc

The cutting speed has the greatest impact on the durability of the tool. It is best to set the cutting speed under the condition of minimum wear of the tool. It can be set according to the hardness and cutting depth of different cutting materials. Try to choose a lower cutting speed to process nickel alloys. Generally, rough milling is 20-50m/min, and fine milling is 40-70m/min;

2) Feed amount f

The feed rate has little effect on the durability of the tool. In the case of ensuring the surface roughness of the machined, a larger feed rate can be selected. Generally, 0.003~0.006mm/r can be selected, and the feed rate cannot be too large. Too much will make the tool wear faster, increase the cutting force, and cause deformation of the parts. Therefore, generally it should not be greater than 0.006 mm/r;

3) Depth of cut ap

The cutting depth has the least effect on the durability of the tool. Generally, a larger cutting depth can be used first, which can prevent the tool tip from cutting in the hardened layer, and can also increase the working length of the tool edge, which is beneficial to heat dissipation. Dimensional tolerance, the depth of cut is equal to the blank minus the size of the part, and cannot be adjusted manually.

Through the use of Kyocera’s special nickel alloy processing blades and Sandvik special nickel alloy blades for processing verification, the part cnc machining results are shown in Figures 5 and 6. The surface effect of the parts is good, and the tool has no obvious wear; the roughness of the parts processed by Sandvik blades is large, which cannot meet the requirements of the drawings. Therefore, Kyocera blades are used for outer circular blades. If a brand needs to be fixed, Kyocera blades are preferred.

8. Tóm tắt thông tin

Aiming at the problem that nickel-chromium-nickel-silicon alloy contacts do not have the ability to process, this article starts from the aspects of tools and process parameters, conducts a lot of process tests, finds a tool suitable for nickel-chromium-nickel-silicon alloy processing, optimizes the processing parameters, and solves the problem. In order to solve the problem of nickel-chromium-nickel-silicon alloy processing, the workshop has been able to process the material from being unable to process it. For the first time, it has the ability to process nickel-chromium-nickel-silicon alloy materials, which greatly improves the processing quality and cnc machining efficiency of parts. The batch production of alloy contacts laid the foundation.

Cửa hàng PTJ CNC sản xuất các bộ phận có tính chất cơ học tuyệt vời, độ chính xác và độ lặp lại từ kim loại và nhựa. Phay CNC 5 trục có sẵn.

Cửa hàng PTJ CNC sản xuất các bộ phận có tính chất cơ học tuyệt vời, độ chính xác và độ lặp lại từ kim loại và nhựa. Phay CNC 5 trục có sẵn.