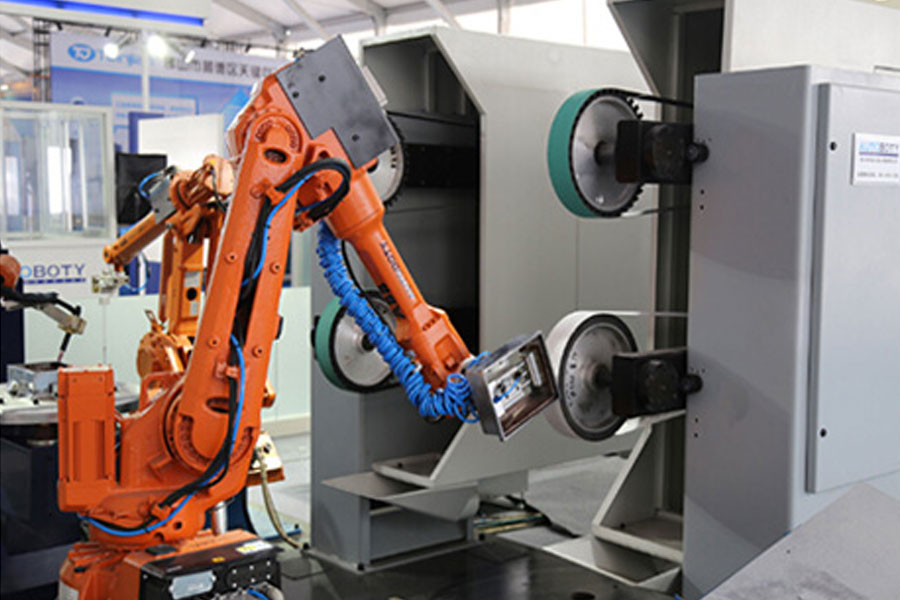

Phương pháp làm sạch của người thao tác công nghiệp

|

Trung Quốc là một quốc gia sản xuất lớn, và cổ tức sản xuất truyền thống đang dần biến mất. Việc thay thế sản xuất thủ công bằng máy móc đã trở thành xu hướng tất yếu trong sự phát triển của xã hội, robot công nghiệp cũng đóng một vai trò quan trọng. Để đảm bảo hoạt động bình thường của robot, người sử dụng phải thường xuyên bảo dưỡng và vệ sinh tay máy. Vậy, các phương pháp làm sạch của máy chế tác là gì? |

The cleaning method of the industrial manipulator: the manipulator needs to be cleaned with high-pressure cleaning equipment when cleaning, but care should be taken to avoid spraying directly to the manipulator, which can easily damage the robot. And also pay attention to avoid using strong solvents such as acetone for cleaning, and not to use a dry cloth to wipe the robot. For the hollow wrist of the robot, it can be cleaned if possible to avoid the accumulation of dust and particles.

Finally, after the cleaning is completed, some petroleum jelly and other items can be added to the surface of the robot’s wrist to facilitate future cleaning. What needs to be reminded is that the manipulator of the robot always needs to be cleaned regularly. This should not be forgotten. The robot can be operated for 24 hours. For example, if the product is taken out and placed on a conveyor belt or a receiving platform, only one person needs to take care of it or one person can watch two or more machines at the same time, which effectively saves labor costs.

In addition, using the mode of industrial manipulator operation, the automatic assembly line can save more plant land, making the whole plant planning smaller and more compact. The time it takes for a robot to produce a product is fixed. In the same life cycle, the output of using robots is also fixed and will not fluctuate. Moreover, the production time of each mold is fixed, and the yield of the product is also high. The use of robots for production is more in the interest of the boss.

Regarding the cleaning methods of industrial manipulators, I hope you can memorize them by heart. In daily production, users must operate the robot system correctly in accordance with the instruction manual, and have a clear understanding of the daily maintenance of the robot. If the robot fails during the production process, you can contact the robot supplier in time to obtain the most effective solution.

Cửa hàng PTJ CNC sản xuất các bộ phận có tính chất cơ học tuyệt vời, độ chính xác và độ lặp lại từ kim loại và nhựa. Phay CNC 5 trục có sẵn.

Cửa hàng PTJ CNC sản xuất các bộ phận có tính chất cơ học tuyệt vời, độ chính xác và độ lặp lại từ kim loại và nhựa. Phay CNC 5 trục có sẵn.